The PLX Wideband AFR (UEGO) combines an accurate, fast response wideband AFR (Air Fuel Ratio) controller with a Bosch LSU4.9 wideband oxygen sensor. The oxygen sensor reaction time is displayed from 10mS/1000mS on the brilliant high contrast OLED display. Pair the SM/AFR with the updated patented DM-6 touch screen MultiGauge, battery voltage is displayed from 9V-20V, sensor life is displayed from 0-100%. The Gen4 also employs the innovative PLX Devices new intelligent health monitoring technology where the oxygen sensor is meticulously monitored every 2mS (488 times per second) to obtain peak performance, accuracy and reaction time. The Gen4 is faster, more accurate, more durable, and uses less power than the Gen3. The new Gen4 Wideband AFR utilizes the next generation in Bosch Wideband Air/Fuel Ratio sensor technology. You can now read an accurate wideband signal through your ECU for datalogging with Crome Pro, Neptune RTP, or Hondata S300.PLX's next generation wideband oxygen sensor controller with intelligent health monitoring technology and current for improved sensor performance. Connect/solder your wideband's 0-5volt output/signal wire to the wire coming from pin D14 and either tape or heat shrink the wire to protect it. Tape off or heat shrink the wire coming from your vehicle's side of the harness and tuck to the side. If your wideband has multiple ground wires, connect ALL of the ground wires to this same location.Ĭut the wire going to ECU pin D14. Some widebands have more than one ground wire. Solder your wideband's ground wire(s) to this wire and either cover with electrical tape or heat shrink. This wire should have continuity to ground at all times.

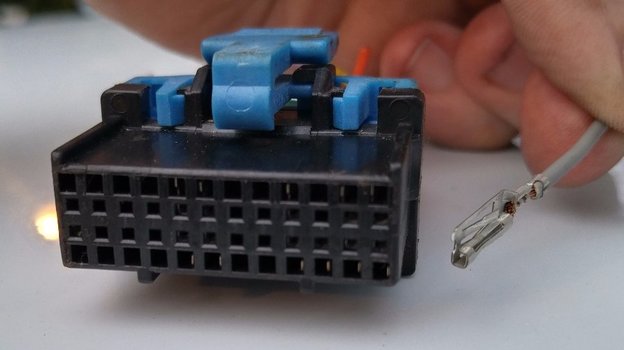

Strip approximately 3/4 inch of insulation off of the wire going to pin A26. Solder your wideband's +12v switched power wire to this wire and either cover with electrical tape or heat shrink. This wire should have +12v with the key turned to the "on" position. Strip approximately 3/4 inch of insulation off of the wire going to pin A25. Make these connections close to the ECU, 3-6 inches from the ECU connectors is perfect. Second, you will be making the connections to your ECU's wiring harness for the wideband's power, ground, and 0-5v signal output. Use a grommet or other method to insulate the wiring so it does not get cut or damaged. Be sure to use caution when selecting a location on the firewall to route the wires through. Route the new wideband sensor's cable/wiring through the firewall and down to your ECU area. If you are using our eTune service with Crome Pro, Neptune RTP, or Hondata S300, then this is the way you should install/wire your wideband.įirst, remove your stock O2 sensor and replace it with your wideband O2 sensor. This will provide an accurate 0-5v output that can be datalogged using Crome Pro, Neptune RTP, or Hondata S300.

The following method for wiring in a wideband oxygen sensor to a vehicle equipped with an OBD1 ECU is our recommendataion for the cleanest install, quickest install, and the best signal from your wideband sensor to your ECU. From our experience, many methods cause poor wideband sensor performance due to electrical interference or insufficient grounds. There are many different ways to wire in a wideband oxygen sensor.

0 kommentar(er)

0 kommentar(er)